Leading the world in

energy absorption

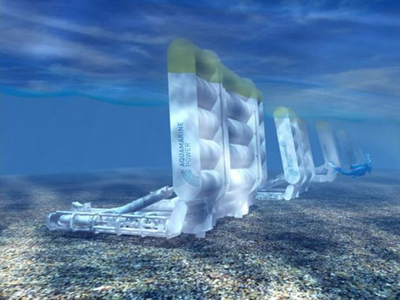

Aquamarine

The Oyster's wave power technology captures energy in near shore waves and converts it into clean sustainable electricity. Essentially Oyster is a wave-powered pump which pushes high pressure water to drive an onshore hydro-electric turbine.

Wave power is generated by wind blowing over the surface of the ocean far out at sea. The action of the wind transmits energy into waves. These waves can travel vast distances with little energy loss before breaking on the shore. The Oyster is designed to harness this energy and convert it into electricity.

The Oyster wave power device is a buoyant, hinged flap which is attached to the seabed at depths of between 10 and 15 metres, around half a kilometre from the shore.

Oleo was commissioned to assist in the design of the Oyster by protecting the buoyant flap "door" and its associated hardware from damaging each other due to "slamming effect" (hard contact) in conditions arising from high amplitude wave and/or associated low water level conditions

Oleo provided a "high tech" door closer using reciprocating buffers between the main moving elements. The velocity sensitive device limited the closing forces to acceptable levels within the design force limits of the Oyster. The Oyster application represents the harshest operating environment of all of Oleo's applications.

The main technical challenges were: